|

The information below is for information only

our store is closed

and we are no longer selling parts.

Maintenance Requirements

Provided by Climate Control Systems

Providing Replacement parts since 1990

www.hearthtools.com

ROUTINE MAINTENANCE

Go

here for some photos of a Un-Happy Pellet insert

Take care of your stove and it will take care of you.

Most of parts we sell locally and on the internet are to people that do not

maintain their Pellet stoves. Motors will wear down if they are not Routinely

cleaned.

The best tool to use for cleaning your stove is a Potato Brush

that you can purchase at any supper market.

ASH REMOVAL

We recommend you do this every 7-10 bags of

pellets.

Routine removal of ash is required to keep the stove in good

working condition. The amount of ash build up in the stove is directly

proportional to ash content of the fuel being used. Typically, Premium Grade

pellets range in ash content from .25% - 1%. A 1% ash pellet will require

removal of the ash four times as often as the best .25% ash pellet. Higher ash

pellet show more tendencies to clinker.

Areas within the stove that require attention routinely are:

1. UltraGrate™ - Although the UltraGrate™ is designed to reduce

the build up of clinkers, cleaning of the grate may be necessary when burning

higher ash content pellets.

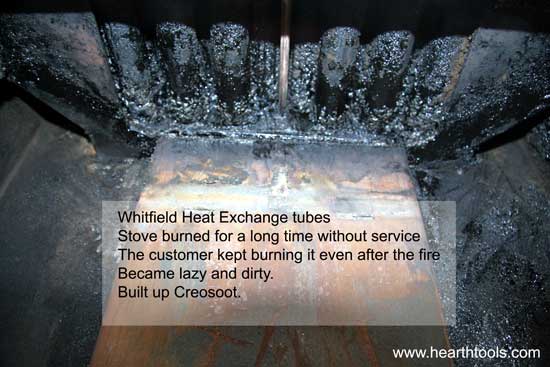

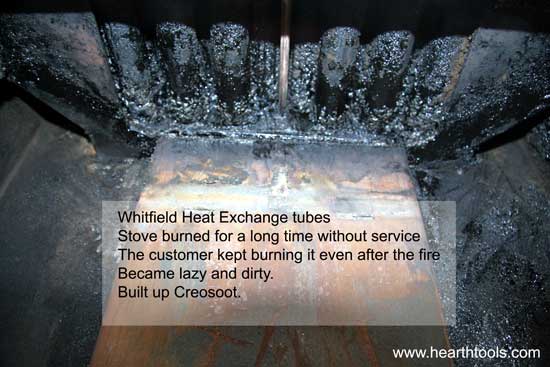

2. HEAT EXCHANGER TUBES – A rod located above the combustion

chamber door is used for cleaning the tubes. Pull the rod in and out a few

times. If the stove is in operation or just shut down, this rod will be

HOT.

A build up of ash on the tubes will lower the heat transfer

efficiency of the stove.

3. ASH PAN – The ash pan, located behind the lower trim piece,

will have to be emptied whenever necessary. If allowed to pile, ash will

restrict in-take air flow to the UltraGrate™ and cause poor burn

characteristics.

4. ASH TRAP BAFFLES – Access to the ash trap baffles

We recommend you do this every 50 bags of pellets.

See photos

photo of adavatage IIT baffle cleaning

(behind the two side firebricks) is obtained by removing the

UltraGrate™ or (Burn pot on older stove) and then loosening the screws that

hold the Brick Retention Plates in place and lifting the clips away from the

stove. After the clips have been removed, remove the side bricks first, then the

center brick from the stove.

Excessive ash build up in the baffle area will restrict exhaust

passages and cause less combustion air to enter the firebox causing a “dirty

burn”.

On OLDER Pre 2000 Advantage stoves

the Baffle is closed in with only a rectangle hole at the t op

It will not be the open style like photo to right. op

It will not be the open style like photo to right.

You will need to remove the Ash trap Baffle, Remove the two

screws, One on top and one on bottom. pull out baffle and you will find more

ash.

ANNUAL MAINTENANCE

We recommend you do this every 75-100 bags of

pellets. (or once a year)

The following should be inspected annually and monitored during

routine maintenance:

1. DOOR GASKET – Close the door on a 1” strip of paper, there

should be slight friction when pulled. Repeat this procedure around various

sections of the firebox door. Repair or replace any poor seal areas as necessary

2. AIR WASH GAP – Check the air wash gap located at the top of

each section of glass. Carpet fibers and/or dust will block proper air flow and

cause “streaks” of ash deposit on the inside of the glass. This area should be

open approximately .075 -.090 inches.

3.

EXHAUST PIPE – Fly ash will collect in horizontal pipe sections reducing exhaust

air flow. The cleanout tee is designed to allow removal without completely

disassembling the vent pipe and should be used on all vertical vent systems.

Because most caps for pellet stove do not have a

screen we find Small birds and or bats in the flue often. Our record for one

stove is 17 birds. So it is a good idea to clean the pipe, cap and check the

combustion blower Just before every season start no mater how many tons you burn

in one year. If you burn more than 2 tons a year clean the pipe or T clean out

every 2 tons.

RULE OF THUMB: When going horizontal to vertical with vent pipe,

a Cleanout Tee is highly recommended.

4. MOTOR HOUSINGS – The blower motors (Combustion and Room Air),

have breather ports on their motors. This allows cooling air to be drawn to the

motor. Dust collects easily at these points. Remove any build up found here.

In Most cased our service Techs remove BOTH blowers

and clean with brush and/or air compressor to remove all house dust and fly ash

from the blower wheel and motors.

Wire diagrams

(large 3mg file has hand written notes)

Includes Pressure reading and auger times for most Whitfield stoves.

vacuum set up we use Standard Metal shop vac with Paper pleated

filter and a Dacron Primary filter to stop the ash from Plugging up the paper

filter.

|

Parts Sales

Parts Sales

op

It will not be the open style like photo to right.

op

It will not be the open style like photo to right.